A Brief Listing of Custom Products Manufactured by Polyrama Plastics ...

Back to Top

Recycle Bin (Yellow)

Beverage Cooler (Multi Colored)

Cattle Paddle (Black C/W Handle)

Dispensing Tank (Green)

Carboy for Wine Making (White)

Flotation Ball (Black)

Electrical Housing (White)

Floats (Yellow and Black)

Coffee Stand (Black)

Pebbling Can (White)

Livestock Torso Prob. (Blue)

HOME

COMPANY PROFILE

PRODUCT OVERVIEW

CARTS AND CONTAINERS

CYLINDRICAL TANKS

ENCLOSED STORAGE TANKS

RAIN CATCHERS

RECTANGULAR TANKS

SPECIALTY TANKS

TOTE BOXES

TRANSPORT TANKS

CONTACT US

MiscellaneousPlayground Equipment

Containment Products

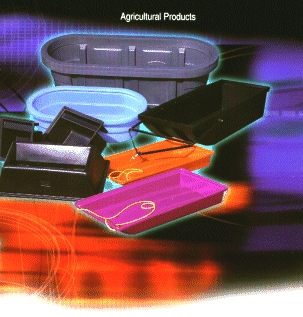

Agricultural Products

Quality

Design

Versatility

Economy

Back to Top

Tube Slide (Yellow)

Basketball Funnel (Brown)

Playground Ball (Green)

90 Degree Elbow (Yellow)

Sectional Canoe (Orange)

Back to Top

Spill Containment Pallet (Grey)

Lid for Spill Containment Pallet (Grey)

45 Gal Drum Tote (Black)

Marine Battery Boxes (White)

Back to Top

150Gal Water Trough (Grey)

Snowmobile Sled (Black)

50 Gal Water Trough (Blue)

Child/Calf Sled (Orange & Purple)

Fence Feeders (Black)

Livestock Saltlick (Black)

Back to Top

Polyrama Plastics prides itself on our Extensive Quality Assurance Program. We utilize our advanced in-house laboratory facilities to ensure product specifications are accurately and consistently met.

Back to TopRotational moulding is a highly versatile manufacturing option that allows for unlimited design possibilities. A wide array of fittings and accessories may be incorporated into the finished product to meet your specific requirements.

Back to TopPolyrama Plastics provides complete product development services for custom rotational moulded products. From the conceptual stage, through production of finished product, our staff's expertise will ensure a quality part. Rotationally moulded components can be color-matched or customized to meet your specific requirements. This form of moulding can accommodate small and large parts for both indoor and outdoor applications. Products are moulded with UV inhibitors to maintain stability and longevity when exposed to the elements. Rotational moulding offers a number of design strengths, including virtually stress-free and uniform wall thickness, as well as strong outside corners.

Back to Top

Rotational moulding has economic advantages over other types of processes. When compared to injection or blow moulding, rotational moulding can produce large and small parts in a very cost-effective manner. Tooling is far less expensive and minor modifications can be made to an existing mould. This makes rotational moulding cost-effective for one-of-a-kind prototypes or large production runs.

"Fabrication, Rotational Moulding and More"